Vol. 1 : Grace Under Pressure

May, 2007

I needed a timer. A simple, stinkin', spring-wound timer that controlled a switch. I'm sure you've seen

them installed in bathrooms here and there, usually to run the I.R. heat lamp in the ceiling. Well, I found a number of them out there but the

$15 to $30 price was a bit too steep for the project at hand. I put the project on a back-burner, and added 'spring-wound timer' to my

mental list of things to keep an eye out for. Sure enough, a few days ago I was wandering a

Goodwill store and stumbled across this

little gem.

If you're new to part prospecting, here's how my thinking goes:

Obviously, right there on the front panel is my 0-30 minute spring-wound timer. When I turned the knob I could feel the electrical

switch make, and the timer started clicking so I was pretty certain that it worked. Now, since the Goodwill folks get a bit

testy when you whip out you multi tool and start taking things apart the rest is guess work. On the front panel we can also see a

pressure regulator, pressure gauge, and a barbed hose fitting. The rear panel had nothing but a small filtered air inlet and the

power cord. So...

The regulator and gauge tell me that this thing must output air from the fitting, and also control its pressure.

The timer tells me that the device also controls how long the air comes out.

Since there is no fitting to attach a source of pressurized air, the device must also contain a pump or compressor of some sort.

The whole thing weighed about 15 pounds (very heavy for it's size) and had a bunch of cooling vents on both sides

reinforcing the notion that there was pump or compressor in there.

The price sticker read $9.99, but it was a BLUE sticker. Goodwill stores have a number of special sale programs. For example, once

each month, usually on a Saturday, everything in the store is 50%. Thursdays are senior citizen days when they get a discount. The

important one in this case is that there is usually a sign near the front door saying "Item with (color) tags are 50% off." Sure

enough when I was there the sign said "Item with BLUE tags are 50% off" so the price of my find was actually $5.56. A bargain for

the timer alone, much less whatever goodies I could harvest, so home it went.

I've learned a number of important lessons in Parts Prospecting, and one is that you NEVER tear apart something until you have some

sort of idea what it is. I once bought an unknown device for $2.00 just to get it's LCD display which would have cost $20.00 new. Later,

after tearing it into a pile of loose parts, I discovered that intact the thing was worth about $800.

I quick Google of the manufacturer led me to their website. It seems that Jobst makes devices that inflate and deflate pneumatic

garments and bandages to assist in blood flow and healing for patients with various medical problems. I also found that the unit that

I had bought was very out of date, and they had no support information (manuals) available online. Then a quick search of ebay, both

items currently being offered and items whose sale was over, showed nothing. Assured that this wasn't worth a bunch of money, it was

time to play.

Back on my bench (and with a fire extinguisher close at hand) I plugged it in and turned it on. Sure enough I could hear a compressor

running inside, and air coming out the fitting on the front panel. I twisted the regulator all the way out (max pressure) and pressed

my thumb over the fitting. The pressure wasn't too high (30 or 40 psi or so) but the pressure gauge pegged. I also noticed that the

air flow cycled. That is, the machine put out air for about 60 seconds, and then the air stopped for about 15 seconds. During the time

the air was stopped, the compressor was still running. It ran, it seemed to work, and it didn't catch fire so it was time to dig into

it.

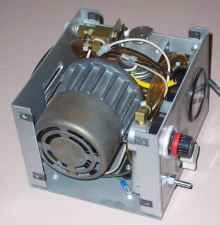

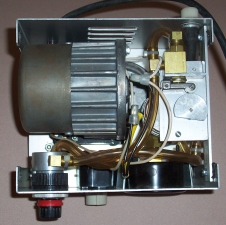

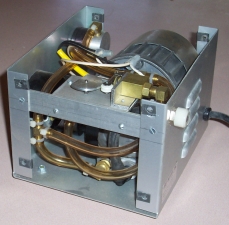

With the cover off, here's what we can determine:

There is no transformer or power supply, so everything electrical in there is running on 115VAC.

The compressor (top left corner of center picture) is completely self contained. Probably rated for medical service and explosion-proof.

The regulator, gauge, and timer are conventional, mounted to the front panel.

There is a pneumatic valve operated by a roller on a short arm. No doubt this is what turns the air on and off.

That roller runs on a cam attached to a clock motor.

No big surprises inside. So, what did my six bucks net me?

| The Haul: |

|

The object of this mission was the timer switch. It turns out that this Dayton switch is still a current product selling at

Graingers for $18.70. It's SPST and rated for 20 Amps. I now have my timer, and everything else goes into inventory. |

|

The timing motor is a Synchron 30RPH (2 minutes per rev) motor and is also available. That is, available if you're willing

to part with $58.75 ! |

|

In the pneumatics misc. category, we have a regulator, and exhaust muffler, a roller actuated valve, a filtered inlet port,

and a number of random brass fittings. No, I'm not going to price all of that out. 8-) |

|

Once I had the pressure gauge out, I noticed that the OEM had simply pasted a new paper face over a standard gauge. With a

fair amount of care I took it apart, removed their paper face, and reassembled it. It's a 2 1/2" Marsh Instruments 0-30PSI

panel mount gauge. It's about $20.00 from Graingers. |

|

The compressor is an odd duck. There are absolutely no markings on it. Since I knew it ran on 115VAC

I powered it up and found it could put out about 50 PSI. I have no idea what kind of CFM it will push, but given that it's a low volume diaphram

type pump I'm guessing well under 1 CFM. Still, it might come in handy some day either for a project, or as barter for something else.

Hmmmm ... vacuum pump for a de-soldering iron perhaps? |

|

Hardware: 4 rubber feet in good condition, 4 rubber shock mounts for the compressor, and a bunch of

other misc hardware including a dozen Nylock style nuts (price THEM at TruValue some day!). And yes, I actually do sort this stuff out into my

parts drawers. 8-) |

|

The chassis and some of the odd mounting parts are aluminum. All together they weigh in at a shade

over 2 pounds. Today (May 2007) my scrap guy is paying $0.42 per pound for aluminum, so eventually this will get me about $0.82. That doesn't

sound like much, but it's about 15% of what I paid for the whole machine! For now it's off to the Aluminum scrap bin which I'll haul to the

scrap guy when it's 100 pounds or better. |

|

Copper: There were some odd bits of wire inside the machine, and the line cord was old and useless.

stripped this netted me 5 ounces of copper. With copper fetching almost $2.00 a pound at the scrap yard, this tiny handful is worth about $0.60.

Like the aluminum it's off to the scrap copper bin until there's enough to take in and sell. |

|

So this is all that's left for the landfill. Most of it is insulation from the wire, and the old

tubing from inside the machine. That makes me feel a little (smuggly) "green". It's cool to get parts cheap, and it's cool to build an

inventory of stuff to have at hand when building something, and it's pretty darn cool to do that at a tiny fraction of what the stuff would

cost new. What's even cooler is reducing the waste flow to the land fill, and recycling metals that won't have to be dug out of the ground

somewhere else on the planet. Now, I'm not an eco-freak but when doing the "green" thing nests so well into that I'm doing, I'm all for it. |

Now, want to see that in terms of dollars and cents?

| The Costs: |

| The Machine |

$5.56 |

| Aluminum |

-$0.82 |

| Copper |

-$0.60 |

| Total |

$4.14 |

| The Values: |

| ITEM |

COST NEW |

COST

USED/SURPLUS |

|---|

| Timer Switch |

$18.70 |

$9.35 |

| Timing Motor |

$58.75 |

$6.25 |

| Roller Air Valve |

$28.25 |

$5.95 |

| Pressure Gauge |

$21.01 |

$8.00 |

| Air Compressor |

$182.00 |

$53.00 |

| TOTAL |

$308.71 |

$82.55 |

Man, I love this hobby. 8-)

John

hbws(at)hackersbench(dot)com

|

|

|

|